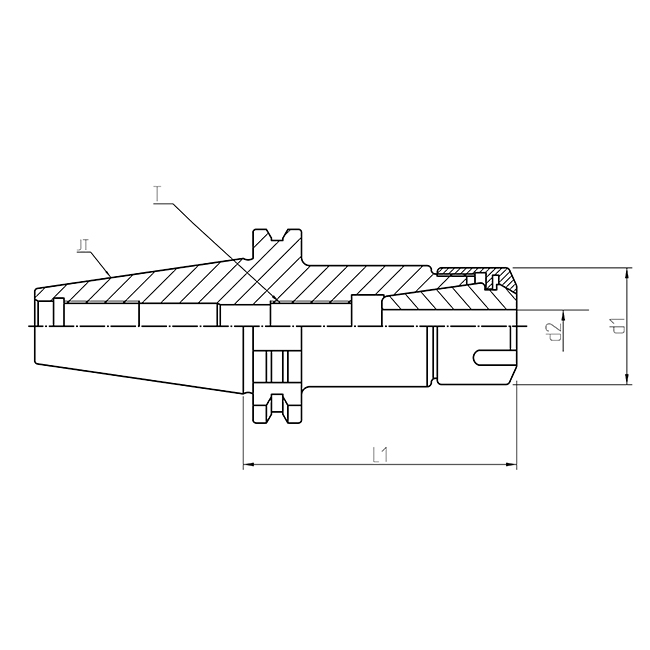

SK(DIN69871)用M型螺母卡盘

SK ER弹簧夹夹用M型螺母卡盘,只有螺母不同于正常的SK ER夹盘。 M型螺母的特点是小直径,可以防止操作期间干扰。 SK ER弹簧夹夹夹铣刀,机械主轴和切割工具等配件。高精度SK柄工具架,平衡G6.3或G2.5供选择,配有DIN6499夹头卡盘可以是直柄切割机夹紧各种尺寸。由于线程是不同的,M型刀具支架不能将螺母更换为其他类型的螺母,如类型,UM类型和GER型螺母。

订购时,请指定表单:A,AD或(AD + B)。

我们专注于生产SK ER弹簧夹夹,我们可以想到样品处理,完善的售后服务和技术支持。期待您的合作!

特征:

1.材质:20crmnti或JIS-SCM415

2.硬度:56-60HRC;

3.渗碳深度:> 0.8;

4.粗糙度:RA <0.4U;

5.使用M型螺母防止干扰。

6.锥形精度≤T3和一部分标准尺寸由德国制造的Diebold标准检查工具测试;

7.超出内部柄锥:≤0.002mm;与夹头的同轴度:≤0.005mm;

8.动态余额可以做:G6.3 12000RPM,G2.5 20000〜30000RPM;

9.适用于镗孔,铣削,钻孔,攻丝,磨削,雕刻加工。

我们的优势

1.好的刚性

2.零件加工和表面处理尺寸的高精度稳定性

3.使用寿命改善切割工具

4.在重切割过程中,振动引起的锥形柄磨损

5. ATC以高精度重复操作

6.外观镀镍,产品是防锈,防腐和耐用性更好。

4.清洁外观和精度稳定

5. -196℃长的低温处理和超长时间热老化加工,减少残余应力并增加硬度和韧性。

订单号。 | 型号。 | L1 | D1 | D2 | T | coll | 扳手 | kgs. |

CD010122.3011070 | SK30-ER11M-70 | 70 | 16 | 1-7 | M6×1P. | er11 | er11m. | 0.5 |

CD010122.3011100 | SK30-ER11M-100 | 100 | 16 | 1-7 | er11 | er11m. | 0.6 | |

CD010122.3011120 | SK30-ER11M-120 | 120 | 16 | 1-7 | er11 | er11m. | 0.7 | |

CD010122.3016070 | SK30-ER16M-70 | 70 | 22 | 1-10 | m11x1p. | ER16 | er16m. | 0.55 |

CD010122.3016100 | SK30-ER16M-100 | 100 | 22 | 1-10 | ER16 | er16m. | 0.65 | |

CD010122.3016120 | SK30-ER16M-120 | 120 | 22 | 1-10 | ER16 | er16m. | 0.75 | |

CD010122.3020100 | SK30-ER20M-100 | 100 | 28 | 1-13 | ER20 | er20m. | 0.7 | |

CD010122.3020120 | SK30-ER20M-120 | 120 | 28 | 1-13 | ER20 | er20m. | 0.8 | |

CD010122.3020150 | SK30-ER20M-150 | 150 | 28 | 1-13 | ER20 | er20m. | 1 | |

CD010122.4011070 | SK40-ER11M-70 | 70 | 16 | 1-7 | M6×1P. | er11 | er11m. | 1.1 |

CD010122.4011100 | SK40-ER11M-100 | 100 | 16 | 1-7 | er11 | er11m. | 1.2 | |

CD010122.4011125 | SK40-ER11M-125 | 125 | 16 | 1-7 | er11 | er11m. | 1.1 | |

CD010122.4011150 | SK40-ER11M-150 | 150 | 16 | 1-7 | er11 | er11m. | 1.5 | |

CD010122.4016070 | SK40-ER16M-70 | 70 | 22 | 1-10 | m11x1p. | ER16 | er16m. | 1.2 |

CD010122.4016100 | SK40-ER16M-100 | 100 | 22 | 1-10 | ER16 | er16m. | 1.3 | |

CD010122.4016125 | SK40-ER16M-125 | 125 | 22 | 1-10 | ER16 | er16m. | 1.5 | |

CD010122.4016150 | SK40-ER16M-150 | 150 | 22 | 1-10 | ER16 | er16m. | 1.6 | |

CD010122.4020070 | SK40-ER20M-70 | 70 | 28 | 1-13 | m14x1p. | ER20 | er20m. | 1.2 |

CD010122.4020100 | SK40-ER20M-100 | 100 | 28 | 1-13 | ER20 | er20m. | 1.55 | |

CD010122.4020125 | SK40-ER20M-125 | 125 | 28 | 1-13 | ER20 | er20m. | 1.7 | |

CD010122.4020150 | SK40-ER20M-150 | 150 | 28 | 1-13 | ER20 | er20m. | 1.8 | |

CD010122.5011070 | SK50-ER11M-70 | 70 | 16 | 1-7 | M6×1P. | er11 | er11m. | 3.8 |

CD010122.5011090 | SK50-ER11M-90 | 90 | 16 | 1-7 | er11 | er11m. | 3.9 | |

CD010122.5011105 | SK50-ER11M-105 | 105 | 16 | 1-7 | er11 | er11m. | 4 | |

CD010122.5011135 | SK50-ER11M-135 | 135 | 16 | 1-7 | er11 | er11m. | 4.1 | |

CD010122.5011165 | SK50-ER11M-165 | 165 | 16 | 1-7 | er11 | er11m. | 4.2 | |

CD010122.5016070 | SK50-ER16M-70 | 70 | 22 | 1-10 | m11x1p. | ER16 | er16m. | 3.9 |

CD010122.5016090 | SK50-ER16M-90 | 90 | 22 | 1-10 | ER16 | er16m. | 4 | |

CD010122.5016105 | SK50-ER16M-105 | 105 | 22 | 1-10 | ER16 | er16m. | 4.1 | |

CD010122.5016135 | SK50-ER16M-135 | 135 | 22 | 1-10 | ER16 | er16m. | 4.2 | |

CD010122.5016165 | SK50-ER16M-165 | 165 | 22 | 1-10 | ER16 | er16m. | 4.3 | |

CD010122.5020090 | SK50-ER20M-90 | 90 | 28 | 1-13 | m14x1p. | ER20 | er20m. | 4.1 |

CD010122.50201055 | SK50-ER20M-105 | 105 | 28 | 1-13 | ER20 | er20m. | 4.2 | |

CD010122.5020135 | SK50-ER20M-135 | 135 | 28 | 1-13 | ER20 | er20m. | 4.4 | |

CD010122.5020165 | SK50-ER20M-165 | 165 | 28 | 1-13 | ER20 | er20m. | 4.6 |

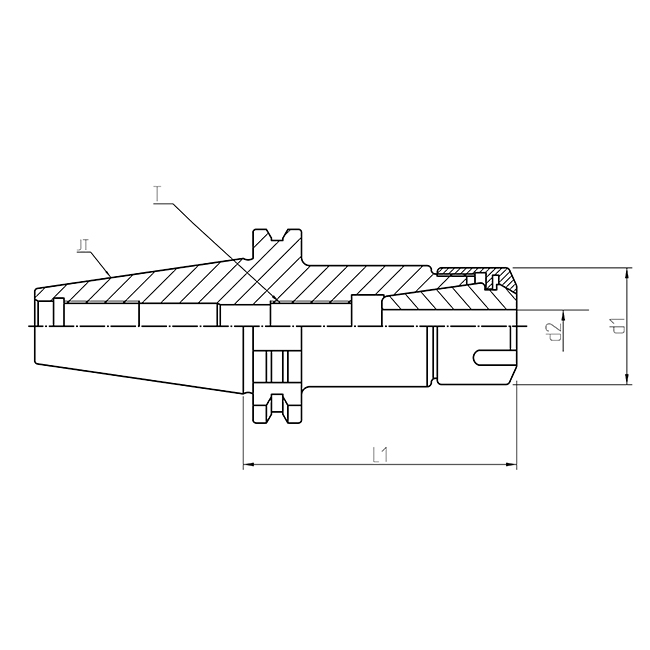

SK(DIN69871)用M型螺母卡盘

SK ER弹簧夹夹用M型螺母卡盘,只有螺母不同于正常的SK ER夹盘。 M型螺母的特点是小直径,可以防止操作期间干扰。 SK ER弹簧夹夹夹铣刀,机械主轴和切割工具等配件。高精度SK柄工具架,平衡G6.3或G2.5供选择,配有DIN6499夹头卡盘可以是直柄切割机夹紧各种尺寸。由于线程是不同的,M型刀具支架不能将螺母更换为其他类型的螺母,如类型,UM类型和GER型螺母。

订购时,请指定表单:A,AD或(AD + B)。

我们专注于生产SK ER弹簧夹夹,我们可以想到样品处理,完善的售后服务和技术支持。期待您的合作!

特征:

1.材质:20crmnti或JIS-SCM415

2.硬度:56-60HRC;

3.渗碳深度:> 0.8;

4.粗糙度:RA <0.4U;

5.使用M型螺母防止干扰。

6.锥形精度≤T3和一部分标准尺寸由德国制造的Diebold标准检查工具测试;

7.超出内部柄锥:≤0.002mm;与夹头的同轴度:≤0.005mm;

8.动态余额可以做:G6.3 12000RPM,G2.5 20000〜30000RPM;

9.适用于镗孔,铣削,钻孔,攻丝,磨削,雕刻加工。

我们的优势

1.好的刚性

2.零件加工和表面处理尺寸的高精度稳定性

3.使用寿命改善切割工具

4.在重切割过程中,振动引起的锥形柄磨损

5. ATC以高精度重复操作

6.外观镀镍,产品是防锈,防腐和耐用性更好。

4.清洁外观和精度稳定

5. -196℃长的低温处理和超长时间热老化加工,减少残余应力并增加硬度和韧性。

订单号。 | 型号。 | L1 | D1 | D2 | T | coll | 扳手 | kgs. |

CD010122.3011070 | SK30-ER11M-70 | 70 | 16 | 1-7 | M6×1P. | er11 | er11m. | 0.5 |

CD010122.3011100 | SK30-ER11M-100 | 100 | 16 | 1-7 | er11 | er11m. | 0.6 | |

CD010122.3011120 | SK30-ER11M-120 | 120 | 16 | 1-7 | er11 | er11m. | 0.7 | |

CD010122.3016070 | SK30-ER16M-70 | 70 | 22 | 1-10 | m11x1p. | ER16 | er16m. | 0.55 |

CD010122.3016100 | SK30-ER16M-100 | 100 | 22 | 1-10 | ER16 | er16m. | 0.65 | |

CD010122.3016120 | SK30-ER16M-120 | 120 | 22 | 1-10 | ER16 | er16m. | 0.75 | |

CD010122.3020100 | SK30-ER20M-100 | 100 | 28 | 1-13 | ER20 | er20m. | 0.7 | |

CD010122.3020120 | SK30-ER20M-120 | 120 | 28 | 1-13 | ER20 | er20m. | 0.8 | |

CD010122.3020150 | SK30-ER20M-150 | 150 | 28 | 1-13 | ER20 | er20m. | 1 | |

CD010122.4011070 | SK40-ER11M-70 | 70 | 16 | 1-7 | M6×1P. | er11 | er11m. | 1.1 |

CD010122.4011100 | SK40-ER11M-100 | 100 | 16 | 1-7 | er11 | er11m. | 1.2 | |

CD010122.4011125 | SK40-ER11M-125 | 125 | 16 | 1-7 | er11 | er11m. | 1.1 | |

CD010122.4011150 | SK40-ER11M-150 | 150 | 16 | 1-7 | er11 | er11m. | 1.5 | |

CD010122.4016070 | SK40-ER16M-70 | 70 | 22 | 1-10 | m11x1p. | ER16 | er16m. | 1.2 |

CD010122.4016100 | SK40-ER16M-100 | 100 | 22 | 1-10 | ER16 | er16m. | 1.3 | |

CD010122.4016125 | SK40-ER16M-125 | 125 | 22 | 1-10 | ER16 | er16m. | 1.5 | |

CD010122.4016150 | SK40-ER16M-150 | 150 | 22 | 1-10 | ER16 | er16m. | 1.6 | |

CD010122.4020070 | SK40-ER20M-70 | 70 | 28 | 1-13 | m14x1p. | ER20 | er20m. | 1.2 |

CD010122.4020100 | SK40-ER20M-100 | 100 | 28 | 1-13 | ER20 | er20m. | 1.55 | |

CD010122.4020125 | SK40-ER20M-125 | 125 | 28 | 1-13 | ER20 | er20m. | 1.7 | |

CD010122.4020150 | SK40-ER20M-150 | 150 | 28 | 1-13 | ER20 | er20m. | 1.8 | |

CD010122.5011070 | SK50-ER11M-70 | 70 | 16 | 1-7 | M6×1P. | er11 | er11m. | 3.8 |

CD010122.5011090 | SK50-ER11M-90 | 90 | 16 | 1-7 | er11 | er11m. | 3.9 | |

CD010122.5011105 | SK50-ER11M-105 | 105 | 16 | 1-7 | er11 | er11m. | 4 | |

CD010122.5011135 | SK50-ER11M-135 | 135 | 16 | 1-7 | er11 | er11m. | 4.1 | |

CD010122.5011165 | SK50-ER11M-165 | 165 | 16 | 1-7 | er11 | er11m. | 4.2 | |

CD010122.5016070 | SK50-ER16M-70 | 70 | 22 | 1-10 | m11x1p. | ER16 | er16m. | 3.9 |

CD010122.5016090 | SK50-ER16M-90 | 90 | 22 | 1-10 | ER16 | er16m. | 4 | |

CD010122.5016105 | SK50-ER16M-105 | 105 | 22 | 1-10 | ER16 | er16m. | 4.1 | |

CD010122.5016135 | SK50-ER16M-135 | 135 | 22 | 1-10 | ER16 | er16m. | 4.2 | |

CD010122.5016165 | SK50-ER16M-165 | 165 | 22 | 1-10 | ER16 | er16m. | 4.3 | |

CD010122.5020090 | SK50-ER20M-90 | 90 | 28 | 1-13 | m14x1p. | ER20 | er20m. | 4.1 |

CD010122.50201055 | SK50-ER20M-105 | 105 | 28 | 1-13 | ER20 | er20m. | 4.2 | |

CD010122.5020135 | SK50-ER20M-135 | 135 | 28 | 1-13 | ER20 | er20m. | 4.4 | |

CD010122.5020165 | SK50-ER20M-165 | 165 | 28 | 1-13 | ER20 | er20m. | 4.6 |